K3-Tent Software Operating Principle

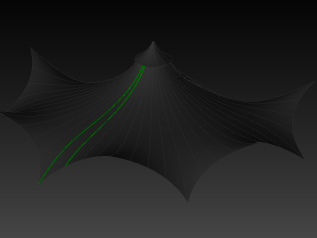

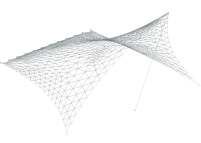

The K3-Tent Suite provides the ability to draw up architecture, construction, and manufacturing documents required to make tent structures of any complexity. K3-Tent software simulates the shape of a "soap film" surface for a specific frame. K3-Tent software simulates a soap film surface shape for a specific frame when retrieving it from the soap solution. The frame may be composed of rigid or stretchable (rubber) ribs.

- The designer creates a frame consisting of straight sections and arcs.

- The designer sets the frame rib boundary conditions (loose, hold fixed, fixed length, etc.).

- The designer specifies if a facet should or should not be used in creating a surface.

- The software automatically calculates the shape of the envelope.

- The designer checks the correctness of the shape by using an isoline plotting tool and a heat normal map.

- The designer marks cutting lines on the envelope.

- The software automatically cuts the envelope into pieces and unfolds the pieces.

- The software can be used to export unfolded pieces to .dxf format.

Designing tent structures with the K3-Tent Software consists of three stages

Finding the shape of an envelope

Dividing the surface into pieces

Unfolding the pieces (pattern generation)

Finding the shape of an envelope

To create a tent structure, the system uses a special object called Frame. A frame is a set of interlinked spatial lines. These lines are straight sections and/or arcs. A frame is a template for the future tent structure. Frame nodes shall correspond to the awning cloth fastening points. Closed topological triangles or squares of the frame are automatically perceived by the system as cloth pieces. Therefore, the designer must make sure that there are no triangles or squares on sections of the structure not to be covered with cloth. The designer's task is to create a frame. The system automatically finds the cloth surface. The implemented algorithm ensures that the cloth surface has no "bubbles," folds, etc.

Dividing the surface into pieces

Creating the cutting pattern for the designed awning cloth is one of the most important and critical stages of the design. The cutting pattern means dividing the awning cloth into individual pieces and then generating a flat pattern for each cloth patch. When dividing the cloth into patches, it should be kept in mind that each patch is a part of the surface with double curvature, which cannot usually be unfolded precisely. We call this unfolding procedure "2D mapping," and it can only be done approximately. The less the cloth circuit’s Gaussian curvature, the higher the accuracy of the 2D mapping. Normally, 2D mapping allows patterns to be generated with linear sizes 1%–2% lower than that of corresponding lines on a curved surface. Therefore, a suitable tolerance must be applied for the cutting pattern. The designer plots mark lines and cutting lines (future seams) on the created 3D model of the awning. Several different line plotting algorithms are implemented in this version of the system, including an algorithm for plotting the shortest path between two arbitrary points.

Unfolding the pieces (pattern generation)

The K3-Tent suite allows the designer to automatically generate cutting patterns for fabric cloth patches. The designer only needs to specify the required piece or select all pieces of a cloth. The cutting pattern can be exported to .dxf format for future use.

System requirements

Recommended system requirements:

Processor 3-GHz ;

Computer memory 16 GB;

Graphics card NVIDIA with 1 Gb memory or more;

Monitor diagonal 20" and more. Screen resolution 1600х1200;

Two-button mouse with a scrolling wheel;

Free 3 Gb of hard disk space;

Supported operating systems Windows 7, 8, 10, 11

Minimum system requirements:

Processor 1.8 GHz;

Computer memory 4 Gb;

Graphics adapter 512 Mb of memory;;

Free 3 Gb of hard disk space;

Standard mouse;

Supported operating systems Windows 7, 8, 10, 11

Step by step instruction

The design process with K3-Tent system can be conventionally subdivided into 6 steps:

STEP 1

STEP 2

STEP 3

STEP 1

Creation of the Frame object on the basis of set of spatial straight lines and circle arcs which defines links and tent constrains.

STEP 2

Definition of boundary conditions for the Frame edges and nodes.

STEP 3

Creation the surface of the tent by the system automatically.

STEP 4

STEP 5

STEP 6

STEP 4

Tracing cutting lines on the surface of cloth. The system cuts the tent surface to patches automatically.

STEP 5

Development patches pattern by the system automatically.

STEP 6

Fabric patterning, cutting, welding and tent surface assemblage.

Suite

The K3-Tent software suite has a modular structure enabling the individual compilation of each work place depending on its purpose. The K3-Tent software suite includes the following components:

K3 geometrical 3D editor

A Form Finding Module

This module is designed for creating a 3D model of an awning. The module allows 3D coordinates to be set for assigned awning nodes and ribs. Define boundary conditions. Based on this information, the module automatically finds the shape of an envelope as the minimum surface area. This significantly simplifies and speeds up the creation of the awning surface, thus ensuring fast and high-quality iterative selection of a large number of shape options.

Cutting Pattern Module

This module is intended for performing design work associated with fabrication of the awning. The module allows cutting lines to be plotted and lines to be marked on a surface. Cut a surface in pieces. Calculate the area and side lengths of the pieces. Generate cutting patterns—that is, unfold the pieces. Transmit data to external systems using graphical format.